A water soluble wax can be applied to make rubber floors more resistant to damage.

Elastomer vs thermoplast vinyl.

Thermoplastic rubber wall cove base 30 pieces 133 32.

Results 1 to 11 of 11 thread.

Linoleum vinyl and rubber are easy to clean.

Thermoplastic vinyl tv thermoplastic vinyl tv is a composite of polyvinyl chloride pvc and is thermoplastic which is a polymer that becomes pliable at high temperatures.

Looking for a versatile and cost effective alternative for natural rubber latex silicone or another compound.

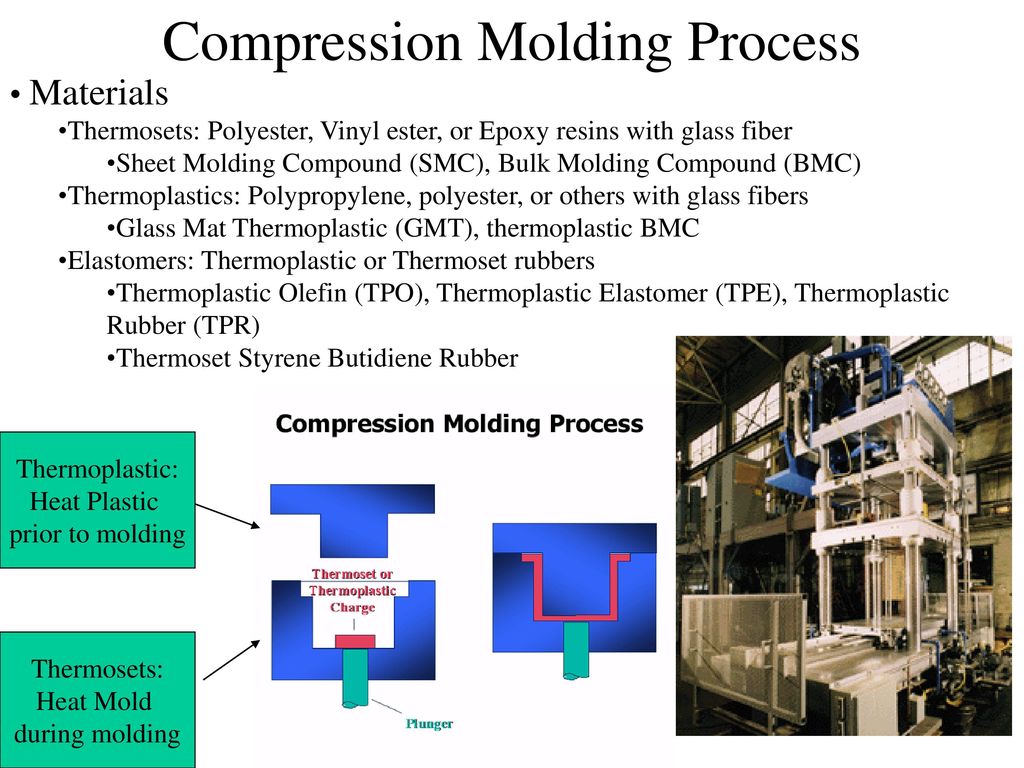

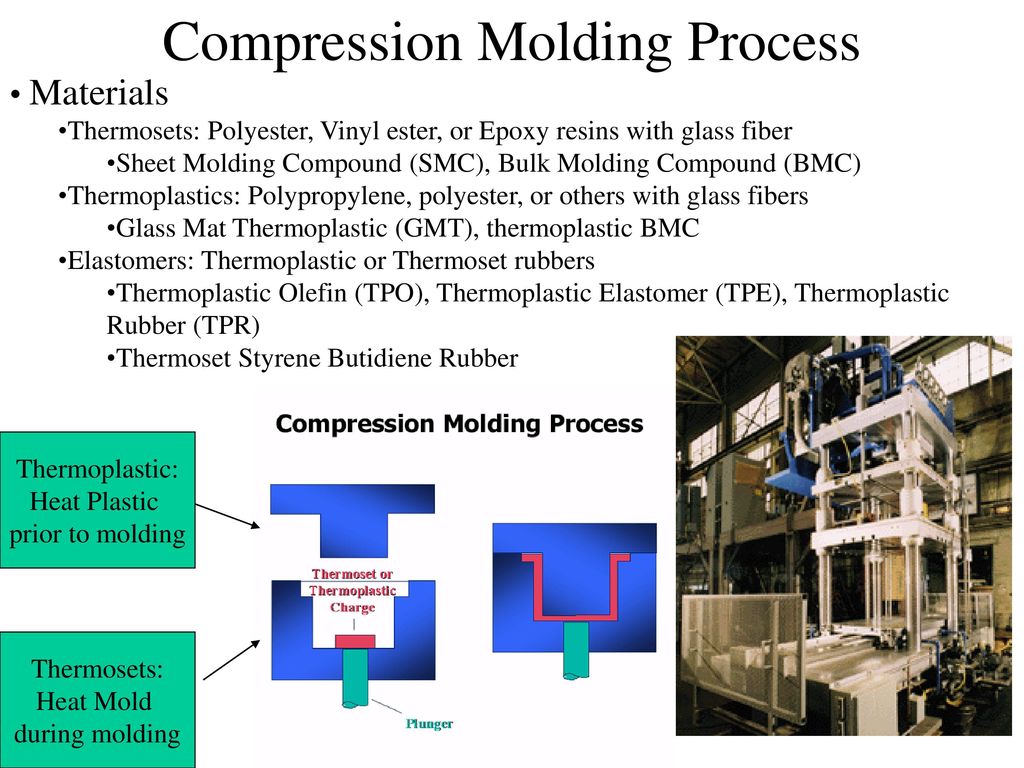

They are thermoplastic vinyl tv thermoplastic rubber tp and thermoset rubber ts.

09 02 2014 03 16 pm 1.

Maintenance of linoleum vinyl or rubber flooring.

Leed projects though will often spec rubber because it is a natural product and requires less energy to produce.

Roppe 700 series steel gray 0 125 in.

This material is often used in the construction industry as electrical insulation.

Thermoplastic rubber and thermoplastic vinyl cove bases are manufactured essentially in the same way.

Flexibility at room temperature x x.

The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross linking bond in their structures.

Thermoset rubber and thermoplastic elastomer are more flexible at room temperature than pvc.

The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials.

High temperature performance x.

Thermoset rubber is heat cured so it will not melt at high temperatures.

Simply wipe up spills sweep or vacuum and dust and mop with warm water and mild detergent.

Thermoset rubber will stay more flexible while approaching low temperatures.

95 of jobs spec vinyl though.

These repeating units are called monomers and are linked together to form the large molecule polymer.

Do not use abrasive pads on rubber floors as they may damage the finish.

Both tpe and pvc are nonallergenic alternatives to natural rubber latex and offer easy sterilization.

The raw materials are introduced to the extruder where the blending and forming processes take place at a temperature high enough to lower the viscosity of the compound so it can be formed into the desired shapes.

Since these are large molecules many varieties can be observed when studying polymers.

Rubber vs vinyl base tread i believe that rubber is considered an upgrade and costs a little more.

Thermoplastic elastomer tpe or polyvinyl chloride pvc could be well suited for your specific product.